Research Validates Antimicrobial Properties of John Boos & Co. Wood Cutting Boards

Used since 1887 by professional chefs, butchers, and in millions of homes, Northern Hard Rock Maple cutting boards by John Boos & Co. are known for their functionality and practicality. New research out of the University of Illinois this month adds further credibility to the hygienic benefits of using Boos Block® cutting boards.

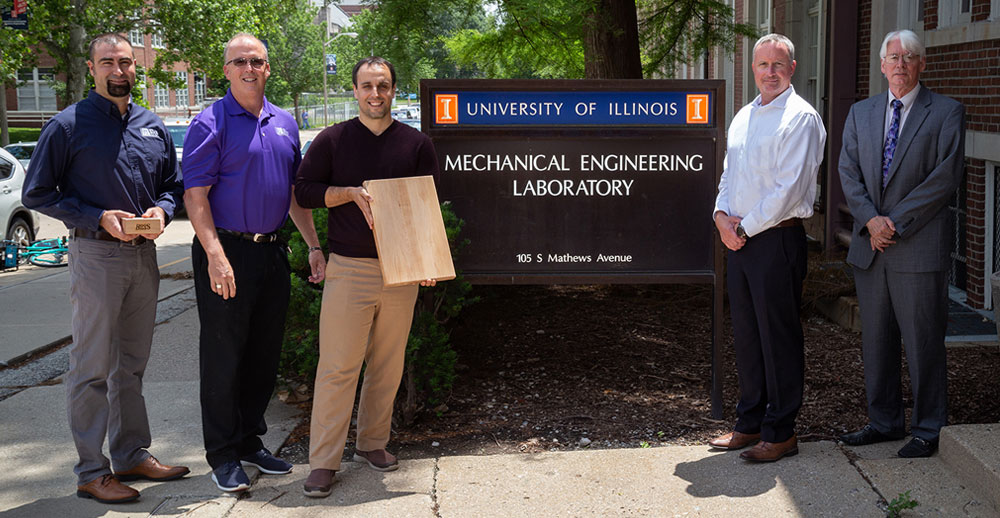

The new study conducted by Mechanical Science and Engineering Professor Nenad Miljkovic and his research laboratory at the University of Illinois, found that the NSF listed Northern Hard Rock Maple cutting boards by John Boos & Co. kill bacteria. Data gathered by the team concluded that application of the NSF listed Boos Block® Mystery Oil and Board Cream on the boards created an “antimicrobial, hydrophobic surface that decreased their surface bacteria to a ‘clean level’ in just three hours” without using recommended board cleaning procedures.

The Boos Block® Mystery Oil and Board Cream form two layers of protection to create an antimicrobial surface. First, the Boos Block® Mystery Oil and Board Cream create a hydrophobic surface by allowing the bacterial fluids to bead up off the surface of the wood and reduce the interaction time the meat fluids can have with the board, thus reducing the adhesion of the bacteria in the fluid to the board. Second, any remaining fluid that may be left behind that did not bead off the surface of the wood is then absorbed into the wood fibers via the Mystery Oil in the board, where the natural occurring enzymes in the Northern Hard Rock Maple kill any remaining bacteria.

Proper board cleaning procedures are still recommended to maintain the board’s surface. John Boos & Co. recommends wiping the board down with a clean disposable towel after each use to remove the food and liquid from the board’s surface. Next, rinse the board with warm soapy water and dry it immediately with a clean cloth. Finally, reapply a layer of Boos Block® Mystery Oil followed by a layer of Board Cream. Never wash a wood cutting board in a dishwasher or immerse it in a sink full of water.

Ted Gravenhorst Jr., John Boos & Co. Vice President of Sales and Marketing, was pleased to reconfirm that the NSF listed John Boos USA grown Northern Hard Rock Maple oil finish cutting boards, kitchen islands, and countertop surfaces are antimicrobial. He summed it up, “Independent research has existed about the antimicrobial qualities of hardwood boards; however, the ‘new-news’ from the University of Illinois lab confirms that the addition of Boos Block® Mystery Oil and Board Cream facilitates the process of killing bacteria, thus creating a clean surface for cooks to use over and over again.”

Professor Miljkovic and his group have extensive knowledge in the area of nanoengineered surfaces and coating technologies. “We’ve been working on developing micro and nanostructured surfaces with antimicrobial function for the past four years as part of a separate collaboration with U.S. Army Construction Engineering Research Laboratory (CERL) and the Department of Entomology,” Miljkovic said. “Teaming up with John Boos & Co., a leader in the foodservice industry, opened up a new avenue of academic research that we had not considered before. Prior to this project, we believed the function of cutting board oil was simply to prevent drying of the wood, but our research showed that it actually enables microbes to absorb into the wood grain, which contain antimicrobial enzymes that kill bacteria. We found that USA grown Northern Hard Rock Maple, used by John Boos & Co. to create cutting boards, was the most effective species of hardwood that contained these antimicrobial enzymes, which kill bacteria.”

Miljkovic’s team’s research shows that the proprietary factory-applied antimicrobial surface of John Boos & Co. Northern Hard Rock Maple cutting boards can be maintained by proper care and maintenance using the Boos Block® Mystery Oil and Board Cream, making the cutting boards a safer, cleaner alternative to other boards on the market today.

John Boos & Co.

Since 1887, John Boos has manufactured butcher blocks from sustainable American hardwoods, which have no carbon footprint, for commercial and residential use. The company is based in Effingham, Illinois. More information is available at www.johnboos.com

The Department of Mechanical Science and Engineering – University of Illinois

The Department of Mechanical Science and Engineering boasts top-ranked degree programs in engineering mechanics, mechanical engineering, and theoretical and applied mechanics. MechSE’s curricula offer students unparalleled strengths in key fundamental areas, such as fluid and solid mechanics, thermodynamics and heat transfer, dynamics and controls, biomechanical sciences, computational science, applied math, applied physics, and chemistry. The unit is under the College of Engineering at the University of Illinois and is led by Department Head and Professor Anthony Jacobi.

Contact

For more information about the antimicrobial study, please contact Mandy Cook, Marketing Specialist. Phone: (217) 347-7701 Ext 1321 Email: mandy@johnboos.com

###

- Press Release From The University of Illinois Department of Mechanical Science and Engineering. https://www.johnboos.com/wp-content/uploads/2024/02/UNIVERSITYILLINOIS-ANTIMICROBIAL-PRESS-RELEASE.pdf

- View the official press release: https://www.johnboos.com/wp-content/uploads/2019/07/PR-ANTIMICROBIAL-STUDY-UOFI-REBRANDED-2024.pdf

- Watch our short video about the antimicrobial study. https://youtu.be/B6KBGgnSS0M

- Proper Cleaning Procedures To Maintain Your Wood Cutting Board Surface:

- Wipe the cutting board down with a clean disposable towel after each use to remove the food and liquid from the board’s surface.

- Rinse the cutting board with warm soapy water and dry it immediately with a clean cloth.

- Reapply a layer of Boos Block® Mystery Oil followed by a layer of Boos Block® Board Cream.

- Never wash a wood cutting board in a dishwasher or immerse it in a sink full of water.